The advent of smart manufacturing marks a significant shift in the industrial landscape, fundamentally transforming how factories operate.

At the heart of this revolution lies machine learning (ML), a powerful subset of artificial intelligence that enables machines to learn from data and improve over time.

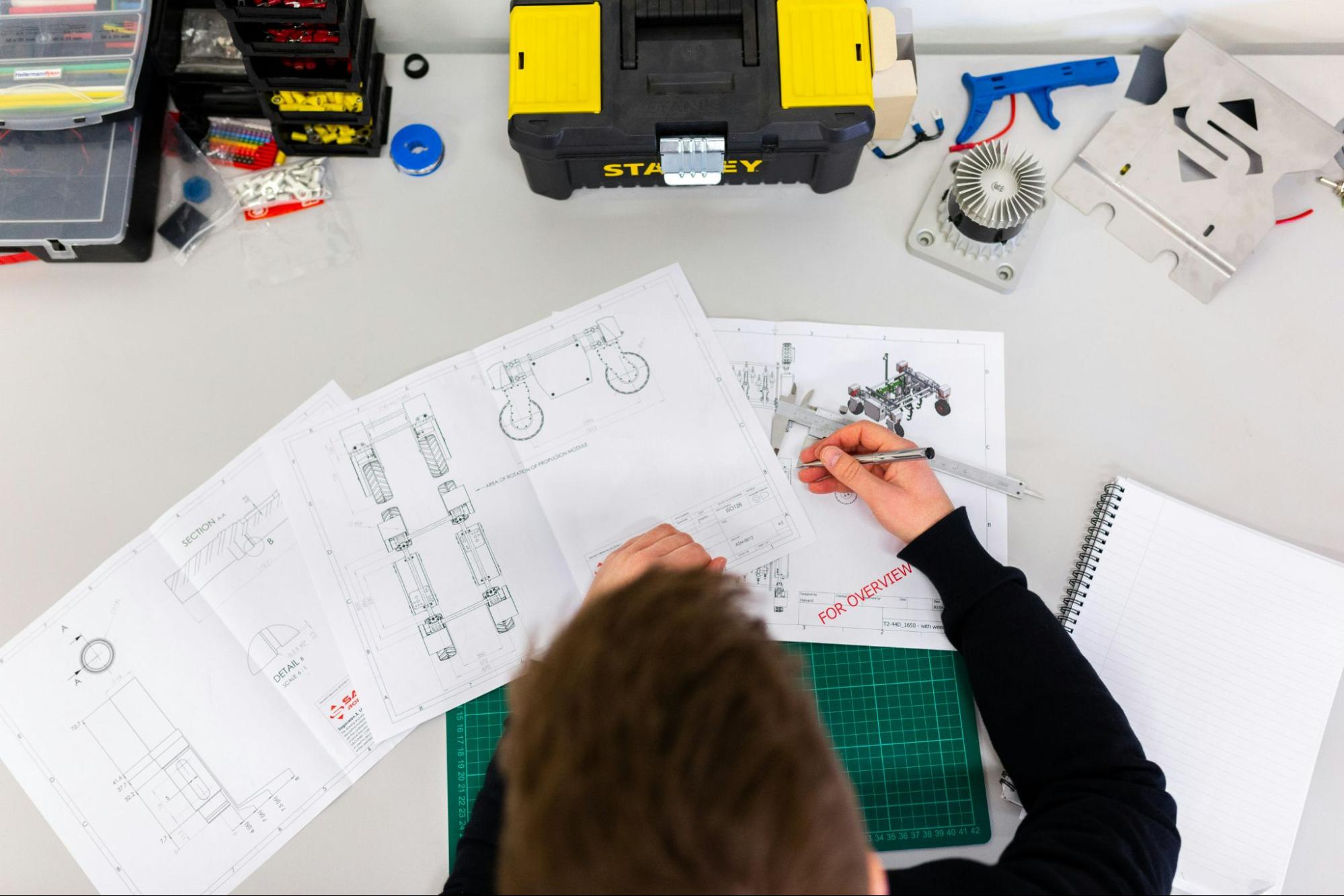

This technological advancement is reshaping the role of engineers in industrial settings, offering innovative tools to tackle complex challenges.

By integrating machine learning into industrial engineering, all types of engineers are now equipped to enhance efficiency, optimize processes, and usher in a new era of intelligent manufacturing.

The Impact of Machine Learning on Engineering Practices

Machine learning is dramatically changing the way engineers approach design and development in manufacturing.

Traditional methods often involve lengthy trial and error processes, but ML algorithms can predict outcomes, simulate conditions, and optimize designs more efficiently.

This shift not only accelerates the development cycle but also leads to more innovative and effective design solutions.

Engineers can now foresee potential issues and rectify them in virtual environments, significantly reducing costs and time-to-market.

Enhancing Quality Control

Quality control is pivotal in manufacturing, and machine learning is setting new standards in this realm. ML algorithms, trained on vast datasets, can identify patterns and anomalies that might elude human inspectors.

This capability is crucial in detecting defects, ensuring product consistency, and maintaining high standards.

Engineers are utilizing these tools to analyze real-time data from the manufacturing floor, enabling them to make informed decisions swiftly and maintain the integrity of the production line.

Optimizing Maintenance and Operations

Machine learning is also transforming maintenance and operational efficiency in industrial engineering.

Predictive maintenance, powered by ML, allows engineers to anticipate equipment failures before they occur, minimizing downtime and extending the lifespan of machinery.

This proactive approach is a stark contrast to traditional reactive maintenance methods.

Furthermore, ML algorithms optimize operational parameters for energy consumption, resource allocation, and workflow management, leading to a more sustainable and cost-effective manufacturing process.

Navigating Challenges and Future Trends in Machine Learning-Driven Manufacturing

The integration of machine learning into industrial engineering is not without its challenges, yet it also opens doors to exciting future trends.

Understanding these dynamics is crucial for engineers to adapt and thrive in this evolving landscape.

Addressing Data Security and Privacy Concerns

One of the primary challenges in implementing machine learning in manufacturing is ensuring data security and privacy.

As industrial systems become more connected, they become more vulnerable to cyber threats. Engineers must, therefore, prioritize robust cybersecurity measures to protect sensitive data.

This involves not only safeguarding against external threats but also managing data access and control internally.

Encryption, secure data storage, and regular system audits are essential components of a comprehensive security strategy.

Bridging the Skills Gap

The shift towards smart manufacturing requires a workforce skilled in both engineering and data science.

This dual demand creates a skills gap, as the current workforce may lack sufficient expertise in machine learning and analytics.

Addressing this gap is critical for the successful implementation of ML in manufacturing.

Companies are increasingly investing in training programs and collaborations with educational institutions to develop a tech-savvy engineering workforce.

This approach not only benefits the current workforce but also shapes the future of engineering education.

Exploring Sustainable Manufacturing Practices

Machine learning is set to play a significant role in advancing sustainable manufacturing practices.

By analyzing vast amounts of data, ML algorithms can optimize resource use, reduce waste, and lower energy consumption.

This not only aligns with global environmental goals but also improves cost efficiency.

Future trends are likely to see a greater emphasis on green manufacturing processes, with engineers at the forefront of designing systems that are both efficient and environmentally friendly.

Realizing the Full Potential of Machine Learning in Industrial Applications

The journey towards fully realizing the potential of machine learning in industrial engineering is multifaceted. It involves not only technological advancements but also strategic planning and continuous learning.

As industries strive to keep pace with this technological evolution, focusing on these key aspects becomes essential for success.

Enhancing Interdisciplinary Collaboration

The complexity of machine learning applications necessitates interdisciplinary collaboration.

Engineers must work closely with data scientists, IT professionals, and operation managers to develop effective solutions.

This collaborative approach is vital for integrating machine learning algorithms with existing industrial processes.

It ensures that the solutions are not only technologically sound but also practically applicable.

Fostering a culture of teamwork and knowledge sharing across different departments is, therefore, a key strategy for industries embracing smart manufacturing.

Leveraging IoT and Automation Synergies

The synergy between the Internet of Things (IoT) and automation is amplifying the impact of machine learning in industrial engineering.

IoT devices collect vast amounts of data from manufacturing processes, which machine learning algorithms analyze to identify trends and make predictions.

This integration enables more sophisticated automation, where machines can adapt and make decisions in real time.

Engineers are increasingly focusing on this synergy to create more responsive and intelligent manufacturing systems, leading to greater efficiency and productivity.

Focusing on Continuous Innovation

In an ever-evolving technological landscape, continuous innovation is crucial. Engineers must stay abreast of the latest developments in machine learning and related fields.

This involves ongoing research and development, experimentation, and adaptation to new technologies.

By embracing a culture of innovation, industries can not only solve current challenges but also anticipate future needs, ensuring long-term success in smart manufacturing.

Key Takeaway

The integration of machine learning in industrial engineering is a game-changer, offering unprecedented opportunities for innovation, efficiency, and sustainability.

While it presents certain challenges, the potential benefits are immense.

As industries navigate this transition, focusing on collaboration, leveraging IoT and automation, and fostering continuous innovation will be key.

Ultimately, this journey is not just about adopting new technologies but about reshaping the future of manufacturing for a smarter, more connected world.